Algorithmic

Method of Problem Solving in the

Engineering Conceptual Design

Zbigniew M.

Bzymek,

Research Professor, Ph.D., zbigniew.bzymek@uconn.edu,

University of

Connecticut, Storrs, Connecticut, USA

On the basis of the academic

experience a teaching method for problem solving in conceptual engineering

design is being developed. It is

expected that it would meet the challenge of ongoing design research and would

be an effective tool providing support for the most difficult phase of design –

solving problems with contradictions. The Brief Theory of Inventive Problem

Solving (BTIPS), that was compiled and developed in research done at the

University of Connecticut, may be a prospective tool for performing such a

task. Derived from TSIP and TIPS – BTIPS slightly differs from those methods.

Modules Principles, Effects and Prediction introduced by IM, in BTIPS are

reinforced and enhanced to meet the newest challenges of engineering pedagogy

and technology. To meet those challenges principles of Size Reduction,

Miniaturization, Nanotechnology and Biotechnology were introduced. The

technological effects were enriched with new developments based on

miniaturization, nanotechnology and biotechnology. Furthermore the application

of Virtual Elements in the Prediction module were proposed to safe

achievements of the current design process.

The tests of functions' separation and minimum information content to

evaluate the derived End Solution as well as several other tests are also the

new recommendations. BTIPS is living, still developing and tested. It is taught

and used, and constantly improving. This paper summarizes the method, its

latest enhancements and shows ways of its applications. Key words: engineering design, problem solving, design principles,

technological effects, designed system, preliminary solution, end solution,

trimming, ideal solution.

Acronyms,

names and abbreviations:

· BTIPS:

Brief Theory of Inventive Problem Solving - the theory compiled and developed

from TRIZ, TSIP and TIPS at the University of Connecticut, USA;

· BS:

Brain Storming - a method of idea generation introduced by Alex Faickney Osborn

in 1961 and based on the Sigmund Freud’s theory of subconscious;

· IM:

Invention MachineTM - a problem

solving software developed in the late 1980s and the 1990s by the Invention MachineTM

Corporation based in Minsk, Belarus and in Boston, Massachusetts, USA;

· IHS

Inc.: Information Handling Services Incorporated - the US company

based in Douglas County, Colorado that acquired Invention MachineTM Inc. on 7th of November 2012;

· TechOptimizer:

Improved edition of Invention MachineTM software;

· GoldFire:

A problem solving software supporting optimization and innovation processes to enhance productivity - developed on the basis of

Invention MachineTM

software, presently being distributed by IHS Inc.;

· TRIZ: Teoriya Resheniya Isobretatielskich Zadatsh

(Russian: теория решения изобретательских задач –

pronounce: teoriya resheniya izobretatielskikh

zadatch) - Theory of Solving Inventive Tasks introduced by

Genrich Saulovich Altshuller in 1946;

· TSIP:

Theory of Solving of Inventive Problems,

the name for TRIZ introduced in the book: Creativity as an Exact Science by G. S. Altshuller - translated

from Russian by Anthony Williams (1984);

· TIPS:

Theory of Inventive Problem Solving - the name derived from TSIP and introduced by the Invention Machine™

Corporation research team under leadership of Valery Tsourikov;

· ES:

End Solution – in BTIPS problem solving procedure, the solution found at

the end of the process that resolves the contradictions, solves the

problem and performs the desired function;

· IS:

Ideal Solution - in BTIPS problem solving procedure, the solution that

satisfies the problem statement, solves the contradictions, requires minimum

information to be described, takes

minimum energy to function and fulfils other requirements of IS tests;

· PIS:

Practical Ideal Solution - in BTIPS problem solving procedure, the IS

that satisfies the conditions of

feasibility, local application, economy or sometimes even requirements of

political and social correctness;

· PrS: Preliminary Solution – in BTIPS module Principles, a solution to

start the problem solving procedure that should solve the immediate problem

even if creating another secondary problem;

· IF: Improving Feature

- in BTIPS Principles module, the intermediate solution aspect that if

considered, is bringing the process

closer to the ES;

· WF:

Worsening Feature - in BTIPS Principles

module, the intermediate solution aspect

that if applied, is pushing the

solution process away from the desired ES;

· DS: Designed System - in BTIPS Prediction module,

the system under design;

· PC

– Physical Component - in BTIPS Prediction module, the Designed System

(DS) the component that has physical representation and performs the required

function;

· VE - Virtual Element

- in BTIPS Prediction module, the element that performs the desired

function but has no physical representation ;

· VS

- Virtual System - in BTIPS

Prediction module, the Designed System (DS) that contains virtual elements;

· VC

- Virtual Component - in BTIPS Prediction module, the component of the Virtual System (VS) that has no physical

representation but performs the required function.

Introduction

In

the fast growing world of competing economies the industrial production plays

the key role. The only chance for the advanced nations to maintain their

leading economy position is to properly invest into technology and education.

This could help them to retain their position which, according to some

predictions may change after 2035 [1]. Engineering is a major part of

industrial potential and design is a decisive part of engineering. The way of thinking is a derivative of

culture and reflects every activity of the society. The engineering design and

problem solving in particular, very much depends on ways of thinking.

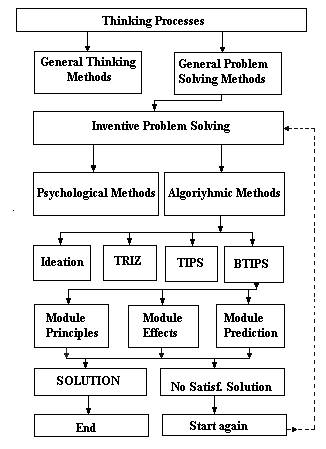

Fig. 1 Structure of thinking processes [15] and the Algorithmic problem solving methods

developed from Altsuller’s

theory of problem solving

The

methods of thinking (Figure 1) are describing procedures of rational decisions

in domains of human activities. Problem solving process is one of those

domains. In economy and technology the

methods of problem solving have particular significance. In the last century

two main approaches to problem solving were developed, psychological and

algorithmic. The most significant among the psychological approach is Osborn’s

proposal of Brain Storming based on Sigmund Freud’s theory of subconscious [2].

One of the most significant among algorithmic approaches is Altshuller’s method

of problem solving. The Altshuller’s method [3] has established a very useful

procedure of problem solving. Nam Suh’s [4] and Stuart Pugh’s [5] contributions

brought however some aspects not considered by Altshuller. The algorithmic

problem solving method introduced by Altshuller [3] and the researchers

following him [6], [7] is a specialized tool for the engineering conceptual

design. It was developed into several mutations. Known commonly as TRIZ was

developed further as TIPS (Table 1). It was formalized in the IMTM

computer program packages [8], [9], [10] and [11]. It was further changed, abbreviated and equipped

with additions at the University of Connecticut and named BTIPS [12],

[13]. While BTIPS was developed mainly

for teaching purposes, it still maintains its ability to be effective tool when

used in practical engineering design and practice.

Modules

of BTIPS have been re-defined and described [12], [13], [14], and [15]. To

formulate the method more clearly the vocabulary of key words, a glossary of

basic terms and definitions, algorithms and formulas, theorems and corollaries

have been stated.

1.

Some characteristics of TRIZ, TIPS and BTIPS

BTIPS is derived from TRIZ

and TIPS. The developments of BTIPS: new principles, attributes and approaches,

components and their interactions as well as physical and virtual elements are

listed in Table 1.

Table 1

TRIZ, TIPS, BTIPS - Similarities and Differences [15]

|

The Method : |

TRIZ |

TIPS |

BTIPS |

|

Number of

Principles : |

40 |

40 |

44 |

|

Number of

Features |

36 |

36 |

40 |

|

Number of

Effects |

36 |

76 |

80 |

|

System

Components |

Supersystem, sytems,

sub-systems |

Supersystem,

sytems, sub-systems |

Super-system, systems, sub-systems, elements, items |

|

Number of modules number |

3 |

3 |

3 |

|

Algorythm |

ASIP |

TIPS

Algorithm |

Algorithm of Ideal Solution Search |

|

Basic

Theorem I |

Not stated

explicitely |

Not

stated explicitely |

1.Minimum Energy of Ideal System |

|

Corollaries derived from

the Basic Theorem I |

Not

stated explicitely |

Not stated explicitely |

1.1The Ideal System has to solve the Basic Contradiction; 1.2. The Ideal System can’t be trimmed |

|

Basic

Theorem I I |

Not

stated explicitely |

Not stated explicitely |

2. Information needed to

describe the Ideal System should be minimum |

|

Corollaries derived from

the Basic Theorem I I |

Not

stated explicitely |

Not stated explicitely |

2.1 Description of the

Ideal System which does not contain redundant information can’t be reduced. |

|

Virtual Components |

Not

introduced |

Not introduced |

Introduced in Prediction module |

|

IS test |

Not

introduced explicitely |

Solving

the Basic Contradiction condition |

Six tests to prove

whether the End Solution is an Ideal

Solution |

2.

Concise Description of BTIPS Application

BTIPS

algorithm consists of five operations:

1. Identify

and define precisely the problem, isolate it properly; the isolation

should be right - isolating not too much

nor too little; adequate space should be left for developing the solution.

2. Begin the BTIPS problem solving procedure by

applying module Effects. Look for the

physical, chemical, mathematical or technological effect that would solve the

problem. If the End Solution (ES) is found, test whether or not it is the Ideal

Solution (IS), if it is not, continue the search and apply module Principles.

3. To apply module Principles the Preliminary Solution (PrS) has to be found first. It

should solve the main problem, even if creating another, hopefully simpler one.

Having the PrS one should define how that

solution improved the design situation (Improving Feature) and how it made the

design situation more difficult (Worsening Feature), and formulate the Basic

Contradiction (BC). Having defined the IF and WF, the principle(s) that would

solve the BC and lead toward the End Solution (ES), should be chosen from the

matrix of principles. If the ES is found and passes the obligatory

tests, it would become the Ideal Solution (IS) and that is the end of the

problem solving process. If it is not the IS, apply the next module -

Prediction.

4. In preparation for application of the module

Prediction one has to describe the Design System (DS), its components and their

hierarchy. One should: a) describe the DS, b) locate the position of the system in the

Super-System and locate the Sub-Systems, the Elements and Items, c) indicate the hierarchy of those components, d)

examine the relations between components, e) eliminate the harmful actions or

change them into neutral, f) change the neutral actions into positive, g)

eliminate the harmful components, h) if after the above changes the Design

System (DS) becomes the End Solution (ES), check whether or not it is the Ideal

Solution (IS).

5. If the End Solution (ES) is still not fulfilling the

expectations: a) add additional physical components, b) propose

what components can be combined, c) propose what components can be still

eliminated or reduced, d) decide where

to delegate the functions of eliminated components; if the ES produced

after those changes would turn to be the Ideal Solution (IS), this is the end

of the process. If not, the Problem

Statement (PS) should be changed and the search for the new ES applying BTIPS

Principles should start from the beginning. Otherwise, virtual components should be introduced in the Designed System (DS) and DS

should be analyzed again. If the DS with virtual components fulfils the

expectations it becomes a Virtual System (VS). It would change again into DS

after the development of technology that would allow to

change Virtual Components (VC) into Physical Components (PC).

Note 1: If after any of the above operations 1 to 5,

the End Solution (ES) fulfils all the expectations, it should be tested whether

or not it is the Ideal Solution (IS), and if it is, this is the end of the

process.

Note 2: To test the End Solution

(ES) one should check six conditions, every one, except for d, necessary but not sufficient to prove that

the ES is in fact the IS. The tests are following:

a) Is the basic contradiction solved by the ES?

If yes, it may be the IS;

b) Is it possible to trim

the ES? If the ES does not contain any unnecessary components to be trimmed, it may be

the IS;

c)

Is the information used to describe ES minimum? If yes, it may be the

IS;

d)

Can functions of the ES be separated? If yes, it may be the IS, but if not,

it may still be the IS however not as attractive as expected;

e) Can the ES exist and

operate using the minimum energy? If yes, it may be the IS;

f)

Is the maintenance of the ES

minimum? If yes, it may be the IS;

g) Are all the tests

except for d satisfied? If yes, it is the IS and it is the end

the process.

If the results of

all the tests,

except for d, are positive,

the End Solution

(ES) become a theoretical Ideal Solution (IS) and the process of

solution search is successfully ended. In order however

to change the IS into Practical

Ideal Solution (PIS), conditions of feasibility,

application, economy or sometimes even

political and social conditions have to be

also satisfied.

3. Application Examples

The examples of BTIPS

problem solving applications are helpful in understanding the process. The

following examples are chosen from literature, consulting and academic

experience.

Example 1. Sand removal from a

jet engine.

Synopsis.

Problem statement: Remove sand from the air passing through a jet engine in a

desert. Solution Method: BTIPS, module

Effects. Physical effect used: centrifugal force. Function attained: Substance removal [9, 10, 11, 12 and 16].

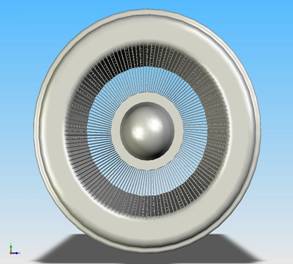

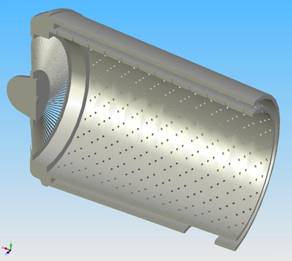

Fig. 1. Views of a jet

engine with additional side container (front and side) designed to take

advantage of the

centrifugal force effect to remove the sand from the air

flow [16]

Solution

Process Description:

The use of centrifugal force to remove sand particles is chosen (Figure 1). Problem statement in this example requires elimination of sand from a

jet engine. From Physics one knows that if the mass is moving along the curve,

it is subjected to the action of centrifugal force. If due

to the rotation of blades a vertex in the air intake is created, the

centrifugal force pushes the sand

particles toward the walls of the engine shell (Figure 1) and outside. This effect is used to solve technological problem of particles

separation from the air moving with high speed. [9, 10, 11, 12, 16].

Example 2. Preventing fire during quenching of steel

parts in oil [9, 10 and 16].

Synopsis.

Problem statement: Prevent fire during steel quenching in oil. Solution

Method: BTIPS, module Principles.

Preliminary solution: cut oxygen supply by covering the container with a

lid. Improving Feature (IF): the lid

prevents the oxygen supply, Worsening Feature: the lid hinders the crane

operation. Basic Contradiction: there should be a lid and there should be no

lid. Principles of Phase Transition was used to find

the Ideal Solution - a lid made out of gas. This example, introduced by IMTM [9],

is a perfect one to illustrate the power of Principles. It demonstrates that

use of matter in phases other than solid, may be a solution to numerous

problems of technology [9], [10], [16].

Solution Process Description: The steel

parts quenching in water has been used in blacksmith practice for centuries. In

industrial quenching water is replaced by oil, improving the process but

creating an oil fire problem. Basic contradiction

is: the lid should be there to cut the

oxygen supply and the lid should not be there because it hinders the crane

operation. The principle of phase transition is used to

solve the contradiction by proposing the lid made out of gas (Figure 2). Gas,

that is heavier than air, stays on the surface of the oil and prevents the

access of oxygen and leaves a free crane access to the container.

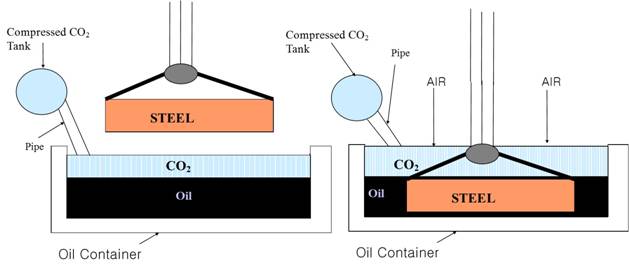

Fig. 2. A

conceptual design of a gas lid covering the container and the quenched part

before (left) and after (right) submersing in the oil [9], [10], [16]

The End Solution applied - is the lid made of gas (Figure 2) [16] is

also the theoretical Ideal Solution (IS). It is not a Practical Ideal Solution

(PIS) however because the use of the suggested least expensive gas CO2 would

be the most economical but not socially correct. For the climate change

prevention reason the other, heavier than air gas, and should be used.

Example 3.

Improving the breaking action of car tires on a pavement [9, 10, and 16].

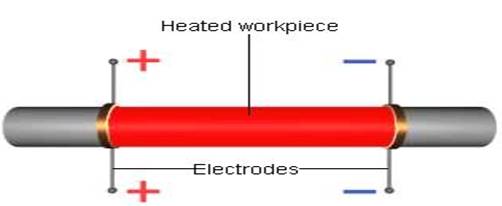

Fig. 3. Schematics of the electric heating

wire connections for heat generation in the pavement suggested by a

TechOptimizer [10]; a system of such hearing wires embedded in the pavement

would keep the pavement warm and dry and breaking action will be effective and

save [16]

Example 3. Improving the breaking action on the highway

pavement [9].

Synopsis.

Problem statement: Prevent tire slipping on the pavement. Solution Method:

BTIPS, module Prediction. System 1: A car tire. System 2: A road pavement.

Subsystem added to system 2: A set of

heating wires. Theoretical Ideal Solution: Heated pavement.

Solution Process Description: In winter

time car’s tires (system No.1) will get cold, which makes rubbers stiff and

hardened. The hardened tires are slippery and do not secure enough friction for

braking [10, 15]. The End Solution is the

introduction of the sub-system – electric heating wires into the system No.2,

the pavement [16]. This is the ES that could became

the theoretical IS. If the solar batteries by the highway could supply the

electricity, this solution would pass an energy optimization requirement. Inserting heating wires into

the pavement is an Ideal Solution (IS).

Solution

Process Description: The problem of car braking on the highway, especially

in a hilly terrain and during bad winter whether, is important for safety and travel comfort. Heating wire system is the

Ideal Solution (Figure 3) [15.] The wires supply heat

into the pavement, improve braking action, and have no negative effects on the

tires nor on pavement [15].

4.

Significance of Problem Solving and Engineering Design

The Alshuller’s

problem solving method is still useful and attractive. It requires however

further development to meet the newest demands of technology. BTIPS has been

created to do it [12], [14], [15] and [16]. The key to “solve impossible” problem

is in the user’s knowledge of science and technology, problem solving tools and

the information about environment, in which the problem to be solved exists.

The world is composed out of matter that could be present in four phases.

Traditionally the solid phase is used the most. Engineers should be prepared however to

understand all the phases of matter and be prepared to apply them in design and

in production of goods. Possibility of solving problems with conflicting

constrains depends often on application of different phase of matter or fields

surrounding them. It determines the success of the product

designed and give the companies and organizations that launched the

product significant advantage over their competitors. The importance of problem

solving knowledge should be brought to the engineering education as early as

possible, starting not only during the beginning years of the university

studies but even in high schools, It should be always in the focus of the

attention of practicing engineers, scholars and industrialists and should also

be brought to the attention of the general public.

Conclusions

Problem

Solving in Engineering conceptual design is the key for successful development

of industrial production, economy and the wellbeing of society. Facing the challenge of the 21st century, general

engineering problem solving research, education and practice has to be

developed further. Engineering design is a foundation for the automated manufacturing

and production. It is important to continue research on engineering problem

solving in conceptual design and manufacturing. It could be done by further

development of algorithmic problem solving methods that can be utilize in

engineering education, research and practice. The correct use of these methods

should be stressed. This is the reason that powerful but simple problem solving

methods should be still developed. They should be supported by development of

the appropriate software. They should be

applied in industrial practice and research

as well as in teaching and learning. Altshuller’s method of problem

solving is still an important tool that should be conserved and developed

further. It is important not only for achieving practical industrial goals but

also for engineering education starting in high schools and during the first

years of the universities studies. BTIPS is the method that can be utilized in

this process.

Acknowledgement

The author is grateful to organizers of CAD/CAM/PDM-2016

in Moscow, Russia for allowing him to present in absentia this paper on problem

solving in engineering conceptual design and perhaps to initialize an internet

discussion. The author appreciates the encouragement of Dr. Valery Tsourikov

during the start and continuation of this research. Many thanks go to IMIM Corporation for the IMIM and TechOptimizer Software

grants. Expression of

gratitude go also to IHS Inc. for the GoldFire software. Thank you for

suggestions that came during the UConn/IM professional engineers courses and

for those that came from the University of Connecticut student class reports

and projects. Thanks for the materials received from institutions and private

individuals that allowed to improve the courses, were

used during them and influenced this article. The author appreciates very much suggestions from students and is grateful for students’

helpful attitude and cooperation. Many thanks go to Steve White of Mechanical

Engineering. University of Connecticut for computer software application help.

References

1.

Dadush U., Stancil B., 2010, “The World

Order in 2050”, The Carnage Policy Outlook: Projected G20 Economic Growth

2009-2050; http://carnegieendowment.org/files/World_Order_in_2050.pdf

; retrieved on 9/14/2016.

2.

Osborn

A. F., 1963, “Applied Imagination.

Principles and Procedures of Creative Problem Solving”, Third Revised Edition,

Charles Scribner’s Sons, New York.

3.

Altshuller

G.S., Creativity as Exact Science.

The Theory of the Solution of Inventive Problems. Translated by Williams,

Gordon and Breach, 1984.

4.

Suh N. P., 1990, The Principles of Design, Oxford University Press, 1990.

5. Pugh S., 1991, Total Design

- Integrated Methods For Successful Product

Engineering, Addison

- Wesley, New York.

6. Petrovich, N. and Tsourikov, V. "The Way to Invention," (in Russian), Moscow, Eureka, 1986.

7.

Tsourikov V. M., 1994, IM Course

Notes, Invention Machine, Cambridge, Massachusetts.

8.

Invention

MachineTM

v.2.1 for Windows. Principles, Effects, Prediction. User Guide, August 1995,

Invention Machine Corporation, 200 Portland Street, Boston, MA 02114-1722 USA.

9.

Invention

Machine Corporation, 1998, TechOptimizer, Version 3.0, Invention Machine

Corporation, 28 State Street, Suite 3600, Boston, MA 02109, USA, tel.

1-617-603-5290; www.invention-machine.com.

10.

TekOptimizer

Version 4.0: Software and User Guide, Professional Edition, Invention Machine Corporation,

200 Portland Street, Boston, MA 02114-17222, USA, 2002.

11.

Invention

Machine, Getting Started with Goldfire, Training for

New Goldfire Users, Document Last Updated August 9, 2010 for v.6.0; Invention

Machine Corporation, 28 State Street, Suite 3600, Boston, MA 02109, USA,

tel. 1-617-603-5290; www.invention-machine.com , www.ihs.com.

12.

Bzymek, Z. M., 2000, Conceptual Product

Design Using BTIPS, DE-Vol.109, recent Advances in Design for Manufacturing

(DFM), ASME 2000, pp. 139-147.

13.

Bzymek, Z. M., 2005, “Brief Theory of

Inventive Problem Solving—Enhanced Approach Using Principles,” Innovations

2005—World Innovations in Engineering Education and Research, (A. Wing et al.

eds.), International Engineering Education and Research (iNEER), Begell House,

pp. 503–516, 2005.

14.

Bzymek, Z. M, 2005.: New Principles in

Conceptual Product Design Using BTIPS, Proceedings of the Fifth International

Workshop on Advanced Manufacturing Technologies, London, Canada, (L. Wang and

X.Y. Liu, eds.), Sponsored by National Research Council of Canada—Integrated

Manufacturing Technologies Institute, pp. 105–110, 2005.

15.

Bzymek Z. M. , 2016, A brief Theory of

Inventive Problem Solving (BTIPS) - an

Approach to the Engineering Problem Solving in Teaching, Learning and Practice,

TRIZ Future Conference Wroclaw. Poland, October, 24-27. 2016, Accepted.

16.

Bzymek,

Z.M., Vahidi S., Spottiswood H., 2007, Solutions of

the 21st century –Teaching

Computer-aided conceptual design. (with S. Vahidi

and Computer-Aided Design &

Applications, Vol. 4, No. 1-4, pp. 459-465, 2007, http://dx.doi.org/10.1080/16864360.2007.10738565.