Reliability

prediction of adaptable-function machine by

exploiting its similarity

characteristics

Qiang Tu,

stud.,

Yi-min Deng,

Jun-yu Wang,

stud.,

Department of

Mechanical Engineering, Ningbo University, Ningbo, China

The adaptable-function mechanical products are versatile

in fulfilling multiple functions, hence are useful in various applications. The

reliability of this kind of product is especially important if compared with

single-function ones. Considering the similarity of its physical structure and behavioral

process between its different adaptable functions, a method for reliability

prediction was thus proposed. By analyzing the behavior similarity, the

similarity of the reliability influence factors, and by exploiting the CBR

(Case-Based Reasoning) theory and that of Fuzzy mathematics, this paper

proposed a concept called comprehensive

similarity, as well as the method for its quantification, which is

subsequently used for the reliability prediction. The paper takes the

reliability analysis of a micro-tillage machine with its function being

cultivating soil as a case study to verify the feasibility of the proposed

prediction method.

Introduction

The adaptable-function machine is capable

of providing a different function from its existing one by varing

part of its physical structure. The similarity

of the behaviors in delivering

different adaptable functions, as well as the similarity of structures

thereof [1], are two of the main characteristics of the adaptable-function

machines. Similarity is one of the commonly used concept in natural

science. Former Soviet scholar Kirpichyov M. V. [2] put forward the three similar theorem, which laid the foundation of research on similarity. The similarity in product

is a premise for product reliability prediction.

The reliability of

mechanical products refers to the capacity of the products to complete the respecified

conditions of use and within the stipulated time. The theory and the technology

of reliability emerged during quired function under

the Second World War, in order to solve the failure problem of military electronic

components and equipment. The reliability of mechanical products is an

important embodiment of product quality. In the reliability research Metler and

Waller [3] discussed the Bayes

estimation of reliability for complex

systems. Johnson [4] studied the early multistage reliability model in complex system,

Todinov [5] investigated

the reliability synthesis problems of complex

system. Menon [6] discussed the role of data mining techniques in the product

development phase, further study [7] studied the

data mining techniques for improving the reliability of system

identification, and paper [8] focused on the life time information sharing research for complicated products.

The adaptable-function product is different as compared

to the ordinary (non-adaptable) products, and the research on reliability of

this kind of products is still rare. To address this problem, this paper attempts

to make an investigation of this problem by focusing on an elaborated study of

behavior similarity and other factors. The basic

idea for reliability prediction to be presented is that, one may predict the

reliability of an adaptable-function product in delivering an adaptable

function if he or she knows the reliability of the product in delivering

another adaptable function, i.e., if the benchmark has been specified. This is

useful because an adaptable-function product may contain quite a number of

functions. With the reliability of the product of any function being specified,

the designers can thus predict the reliability of the product in delivering all

other functions, which will provide the designer helpful information if he or

she wishes to refine the design, e.g. by enhancing the reliability of the

product for all functions.

1. Similarity analysis of adaptable-function machine

1.1 Analysis of behavior similarity

The adaptable-function

machine

exhibits similarity of the behaviors in delivering

different adaptable functions. To study

this behavior similarity, we adopt the “physical state change” method for

behavior representation [9]. Take

the similarity analysis of digging farmland, transport goods and spraying

function of micro tillage machine for example. Tables

1-3

respectively express the three functions and their corresponding physics state changes of this machine. To

facilitate elaboration, we indicate the function

of digging farmland as F1, the function of transforming goods as F2, and the function of spraying pesticide as F3.

Table 1

Physical state

changes of the digging

farmland function

|

Function |

Digging farmland F1 |

|||||

|

Sub-behaviors |

Press the switch |

Turn on the circuit |

Start the engine |

Push the piston |

Rotate the crankshaft |

Rotate the small sprocket wheel |

|

Drive link chain |

Rotate the big sprocket wheel |

Transmit motion to small sprocket chain |

Rotate the drive shaft |

Drive the farming tool |

The farming tool dig the farmland |

|

Table 2

Physical state changes of the transforming goods function

|

Function |

Transforming goods F2 |

|||||

|

Sub-behaviors |

Press the switch |

Turn on the circuit |

Start the engine |

Push the piston |

Rotate the crankshaft |

Rotate the small sprocket wheel |

|

Drive link chain |

Rotate the big sprocket wheel |

Transmit motion to small sprocket chain |

Rotate the drive shaft |

Drive the tire |

The tire transport goods |

|

Table 3

Physical state changes of the spraying pesticide function

|

Function |

Spraying pesticide F3 |

||||||||

|

Sub-behaviors |

Press the switch |

Turn on the circuit |

Start the engine |

Push the piston |

Rotate the crankshaft |

Spray device movement |

Volume pressure changes |

Suction drainage |

Spraying pesticide |

In order to compare

similarity degree of these physical states changes more accurately, we

introduce the similarity evaluation decision table (see Table 5), with

the values given by domain expert. The Table 4 shows the

details of “dive the farming tool ” and the “drive the tire ” sub-behaviors in energy, material and

signal(mainly considered the outputs situation ).

Table 4

Energy, material and signal details of two sub-behaviors

|

|

Energy |

Material |

Signal |

|

Dive the farming tool |

kinetic energy |

Farming tool |

component motion |

|

Drive the tire |

kinetic energy |

tire |

component motion |

Table 5

Similarity evaluation

decision table

|

Number |

Similar situation of energy, material and signal |

similarity |

|

1 |

Energy, material and signal are all the same in the

physical state changes |

1 |

|

2 |

Energy, material are the same, signals is different in

physical state changes |

0.8 |

|

3 |

Energy, signal are the same the flow of materials are

different in physical state changes |

0.7 |

|

4 |

Material, signal are the same,the

flow of energy are different in physical state changes |

0.6 |

|

5 |

The flow of energy are the same, the material and

signal are different in physical state changes |

0.5 |

|

6 |

The flow of material are the same, the energy and

signal are different in physical state changes |

0.4 |

|

7 |

The flow of signal are the same, the material and

energy are different in physical state changes |

0.3 |

|

8 |

The flow of material, energy and signal are all

different |

0 |

With the quantitated physical state changes of these three functions, we can employ the classic Jaccard coefficient

to evaluate the similarity between their corresponding behaviors.

Assume the behaviors corresponding to Function i and j are to be compared, whereby

Ak is the similarity value of physical state changes, k is the serial number

of the sub-behaviors, n is the total number of

compare process, then we can get the similarity of i

and j as Equation (1):

(1)

(1)

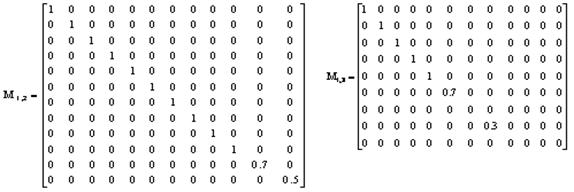

In fact, in the

current example k is from 1 to 12 (n = 12). According to the similarity evaluation decision table, we can get the similarity matrix of these three functions as below.

By using Equation

(1) to calculate, the similarity values of the behavior “digging

farmland” and the

others other two behaviors are S12=0.93; S13=S123=0.67. The data show that, the

higher the similar degree of material, energy and

signal, the higher the similarity of the

corresponding behaviors or behavioral processes.

1.2 Analysis of similarity of reliability influence factors

The characteristics of the

reliability

shows that the fault reasons of a mechanical product can be of diversity and complexity, determined by the

working environment, the quality of the product itself, and so on, all of which are referred to as the reliability influence factors. The adaptable-function machine works with different functional components, and it changes

its output function through the conversion of

functional components. In order to consider the reliability influence factors of the

adaptable-function machines more

comprehensively, we select the working environment, product quality, working time, working load as the basic influence factors. The working environment factor include the environment temperature, acid and alkali conditions, lubrication

conditions. The quality factor include materials quality, processing

technology and others that may

influence the quality of the constituent components. The factor of working time is used due to the

fact that the adaptable functions may be used unevenly. The working load factor may be used according to the specific

application, for example, in the previous example, the load for “transporting

goods” function can be the weight of the goods,being transported, and the load corresponding to “spraying pesticide”

function can

be the amount of pesticide to be sprayed, etc. Table 6 shows an

influence factor decision table given by the domain expert.

Table 6

Influence factor decision table

|

Influence factors |

Hierarchical and scores |

|||

|

Environment |

Very good (1) |

Good (0.8) |

General (0.6) |

Poor (0.4) |

|

Quality |

Very good (1) |

Good (0.8) |

General (0.6) |

Poor (0.4) |

|

Working time |

Short (1) |

General time (0.8) |

Long time (0.6) |

Very long time (0.4) |

|

Working load |

Very light (1) |

General weight (0.8) |

Heavy (0.6) |

Very heavy (0.4) |

Note

that the values given in Table 6

are only as a demonstration of the proposed methodology. The actual values

depend on the specific domain of application and should be specified by the

respective domain experts. For the above case of micro tillage machine, reliability influence factor values may be

given as the one showed in Table 7.

Table 7

Reliability influence factor values for micro tillage machine

|

|

Environment |

Quality of artifacts |

Working time |

Working load |

|

Digging farmland |

0.65 |

0.86 |

0.83 |

0.87 |

|

Transform goods |

0.76 |

0.81 |

0.79 |

0.65 |

|

Spraying pesticide |

0.67 |

0.73 |

0.70 |

0.75 |

To study the similarity degree of the

reliability influence factors among these functions, this paper uses the concept of closeness degree in Fuzzy mathematics. Set the A1, A2 as the two

functions

to be compared, U=![]() is reliability influence

factors,

is reliability influence

factors,![]() is the corresponding

feature vector sets,

is the corresponding

feature vector sets, ![]() is the weight of each influence factors. For the

ease of calculation, we chose equal weights for the current example. The closeness degree between function 1 and function 2 is thus

given as below.

is the weight of each influence factors. For the

ease of calculation, we chose equal weights for the current example. The closeness degree between function 1 and function 2 is thus

given as below.

(2)

(2)

By

using Equation (2), the reliability influence

factor closeness degree between digging farmland and transforming goods is 0.87, and

that between digging farmland and spraying pesticide

is 0.88.

1.3 Calculation of

comprehensive similarity

As

mentioned before, the prediction of the reliability of an adaptable-function

machine is applicable

if its reliability in delivering one of the adaptable functions has been known

a priori. This in turn is applicable by exploiting the similarity of physical state changes and that of the reliability influence factors between the one to be predict and the

one that is specified (the benchmark). For example,

we may make use of the reliability of the function “digging

farmland” to predict the reliability of others functions for the micro tillage machine. To implement

this idea, this paper introduces the concept of “comprehensive

similarity”, which

incorporates both the similarity

of physical state change and that of influence factors. The

comprehensive similarity formula is

![]() (3)

(3)

where ![]() is behavior similarity weight coefficient,

is behavior similarity weight coefficient, ![]() is the influence factors closeness degree weight coefficient.

To simplify the calculation, we again use equal weights, i.e. both 0.5 for the

micro tillage machine. In this way, we can get the comprehensive similarity

between digging farmland and the other two functions as,

is the influence factors closeness degree weight coefficient.

To simplify the calculation, we again use equal weights, i.e. both 0.5 for the

micro tillage machine. In this way, we can get the comprehensive similarity

between digging farmland and the other two functions as,

ST1,2 =0.5*0.93+0.5*0.87=0.90,

ST1,3=0.78.

2. Reliability prediction of the

adaptable-function machine

According to the reliability prediction model of

mechanical products

[10], the failure effects of a partial system to the whole system can be classified according to the following

types of system configuration.

(1) Serial system. This means an failure at any part will result

in the failure of the whole system.

(2) Parallel

system. Paralleling system means all the points

and institutions failure, the system will failure.

(3) Mixed system. Such a system contains both serial parts and parallel parts.

As discussed above, an adaptable-function machine includes shared (common) parts and

separate functional components (for

individual adaptable functions respectively), hence the shared parts can be regarded as the serial-type system, and the functional components can be regarded as the parallel-type system. This

provides us the theoretical basis for the above strategy in predicting the

product reliability for one adaptable function by exploiting the reliability of

the product for another adaptable function. Figure 1 shows the configuration of micro tillage machine, from the

perspective of the above classification criterion, when it works normally.

Fig. 1 System

configuration of the micro tillage machine

To measure the reliability of micro tillage machine, we propose

to use the life time of the machine under

normal working condition. For

example, we can randomly select 5 micro tillage machines with the same brand and the same model, analyze and record the life time of digging farmland function (we have

used the digging farmland function to predict the other two functions), as shown in Table 8.

Table 8

Life times of five micro tillage machines

|

Name |

A1 |

A2 |

A3 |

A4 |

A5 |

|

Life time (*104h) |

3.68 |

4.59 |

5.55 |

3.36 |

5.23 |

The average life time is hence 44820 hours. According to the comprehensive similarity values showed above, we can calculate the life time of transforming goods function as 44820*0.90h=40338h, and

the spraying pesticide function life time as 44820*0.78h=34960h.

The above solution

shows that the accuracy of the reliability prediction is not only affected by the

comprehensive similarity results, but also by the benchmark

reliability

value. To improve the

accuracy of benchmark reliability measurement and that

of the similarity calculation are both important to increasing the accuracy of the

reliability prediction.

Conclusion

The above sections have presented a strategy of

reliability prediction of a specific type of machine, namely the

adaptable-function machine. This

prediction method is based on similarity of the product behaviors by which different

adaptable functions are delivered, as well as the similarity of reliability

influence factors. With this strategy as well as the implementation

methodology, the designer can predict the reliability of the product under all

situations once its reliability for any one adaptable function is known, hence

it can considerably reduce the workload of reliability test for all of its

adaptable functions. As for the

specification of an initial reliability

value, i.e. the benchmark reliability, we proposed to use the life time test as

a measurement. Future work should include a study of other methods for the

benchmark reliability specification, as well as on how to use more subjective

evaluation method for the similarity of product behaviors (via physical state

changes) and that of the reliability influence factors.

Acknowledgement

The authors gratefully acknowledge the supported by National Science Foundation of

China (Grant NO.51375246).

References

1.

Qian L. Gero

J S. Artificial

Intelligence in Engineering Design, Analysis and manufacturing 10(4),

289-312(1996).

2.

Kirpichyov M. V. Similarity theory. Science press, 1955.

3.

METLER W A,

WALLER D A. IEEE Transaction on reliability 32, 111-114(1983).

4.

JOHNSON V E.

IEEE Transaction on reliability 54 (2),

224-231(2005).

5.

TODINOV M T.

International Journal of Reliability, Quality and Safety Engineering 13 (2), 127-148(2006).

6.

MENON R, TONG L

H, SATHITAKEERTHI S. Quality and Reliability Engineering International 20 (1), 1-15(2004).

7.

SAITTA S,

RAPHAEL B, SMITH F C. Advanced

Engineering Information 19 (4), 289-298(2005).

8.

ANG Xi-feng, ZHAO Liang-cai, SHU Shi-jie. Material Science Forum 3, 532-533(2007).

9.

Y.-M. Deng, D. Zheng. Chinese Journal of Engineering Design 15 (3), 164-169(2008).

10. J.-Q. Wang, C.-M. He. Journal of Sicuan Ordnance 29(3),

17-19(2008).