3d Modeling And Use of Animation in

Industrial Facilities

Prof.Dr. Kamuran GÜÇLÜ,

Prof.Dr., Kamuran.guclu@gedik.edu.tr,

Asc.Dr. Kayhan

KAPLAN,

Asc.Dr., kayhankaplan@hotmail.com,

Seda Muratoğlu,

sdmuratoglu@gmail.com

Gedik University Faculty of Architecture and Fine Arts. Istanbul/Turkey

By the development of technology, the usage of three dimensional (3D)

images which are created by computers

are increasing in all areas. 3D technology which is used in Industrial facilities

for many years, reached the final point with animations and simulations. This

study was carried out in Gedik Casting Welding factory in Istanbul (Turkey).

All factory with an area of 25,000 m2,

is modeled in three-dimensional by a computer realistically. Also manufacture

and production process in the factory animated in real-time. Results of this

study are used for different purposes. First, the animation of production

process revealed the advantages and disadvantages of the factory in terms of efficiency

and planning. This study will be an important guide for establishing these

types of facilities in the factory. On the other hand these high-quality images

and animations can be used in both national and international advertisement of

the factory. Thus, the opportunity to feel being in factory and evaluation will

be provided without visiting the factory.

Introduction

In parallel with the development of Information Technology, new ones are

being added to the graphic processes realized by three-dimensional cards (Alpha

blending, Environment mapping, Fogging, Shading, Gouraud shading, Lens flaring,

Texture mapping, Mip mapping). While the computer games are shown as the

propulsive force in the development of the three dimensional technology in the

personal computers today, in the near future, three dimensional applications

will be a part of the operating system and the business applications will be

three dimensional as well (Kaplan

et al., 2009).

Three-dimensional (3D) visualization of simulation results is an important

and useful technique for engineering simulation (Rohrer, 2000). It allows users

to examine the complex processes of production plants in real-time and from

different aspects. 3D visualization represents physical working environments

with 3D graphics objects, and presents abstract simulation models by means of

computer animation. It produces the visual presentation of what is to happen in

the real world, thus providing users with a facility to study and analyze the

production and logistics behaviors of industrial manufacturing operations

(Zhong and Yuan, 2011). Through 3D visualization, users can obtain information

not only from reports and statistical results, but also from the visual

scenarios of the entire operational cycle within production plants, including

supply chains, inventory, resource utilization, flow of materials, and the

overall operation.

1.

Field of Study

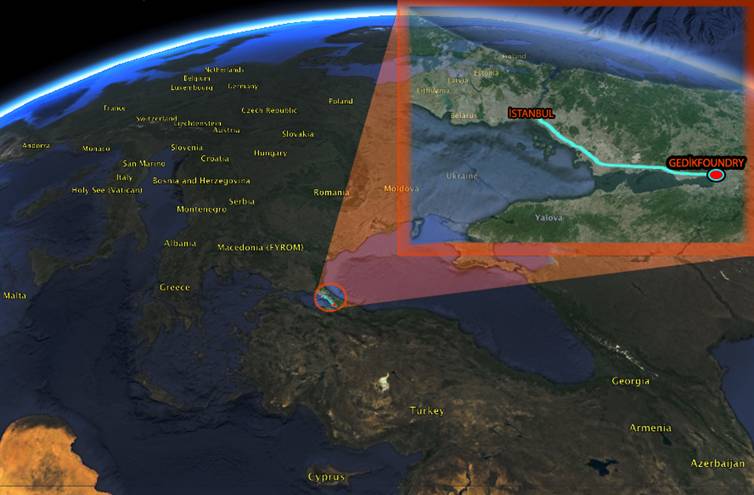

This study

was carried out in Gedik Casting and

Valve Factory; Istanbul-Turkey. Gedik Casting Factory is located in Hendek Organized

Industrial Zone where is 160 km far from Istanbul City Center. Factory has

25.000 m2 covered area and 25.000 m2 open area

(figure 1). Iron casting, Spheriodal Graphite Cast Iron, Steel and

Stainless Steel, Bronze and Sand Casting products were manufactured in this

factory.

Fig. 1. Gedik Casting

Factory and Location

This factory

is established 4 main modules: Sand Preparation System, Sinto Casting Line,

Melting Furnace, Cleaning and Grinding.

These modules

also work with Core room, Dust Collection Systems, Furnace Systems. Manufacture

capacity of the factory is 25.000 tones per year.

Factory

Features and modeled departments:

• Horizontal flaskless molding line with capacity of 250 mould/hour.

• Steel casting automatic molding up to 400 kg with resin-cored molding.

• Cooling and sorting conveyor system for effective casting handling.

• Two fully automated independence sand plants.

• Steel Casting: single piece: 10 - 1.000 kg.

• With the size of the mold with a molding machine 500x600x250/250mm.

• FBOX III Unrated weighs 1kg-50kg cast iron (figure 2).

Fig. 2. Fbox:

photorealistic modeled

• Large parts of the molding is possible of except that FTL.

• Ductile iron can be cast in one piece up to 2000 kg.

• 4 medium frequency induction furnaces.

• Machining workshop capabilities.

• Automatic continues grinding and trimming system.

• Fully equipped metallurgical laboratories and NDT.

• MFOuUllyLDeqINuiGppLeIdNEmSetallurgical laboratories and NDT.

• 2 FBOX-III flaskless molding lines with the dimensions of 500X600x250

[mm].

• 1 box-shaped molding line with the dimensions of 1000X800X300[mm].

• 1 FTL (steel casting) alphaset resin sand molding line.

• Core: The cores are made by Shell and Cold Box Core Machines.

Fig. 3. Fbox line

modeled

2. Method

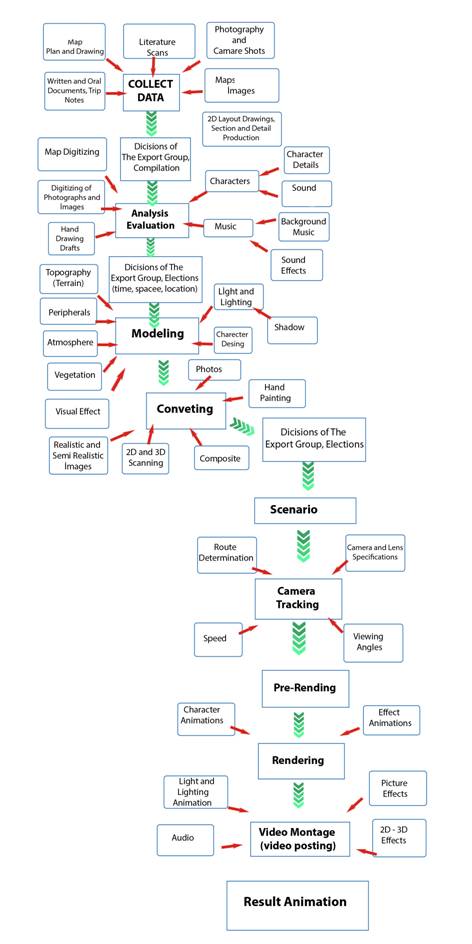

Research was commenced primarily with the modeling of Gedik Casting

Factory. This long-run research required bringing together different methods

since it was based on a study that had scientific, social, and aesthetical features.

With this objective in my mind, a path in the form of Data Collection,

Analysis, Modeling, Overlying, and Rendering was followed. Modeled in the

Factory of Gedik Casting is shown in Figure 2.

Fig. 4. Flow

chart of the study

3. Process Modeling and Animation

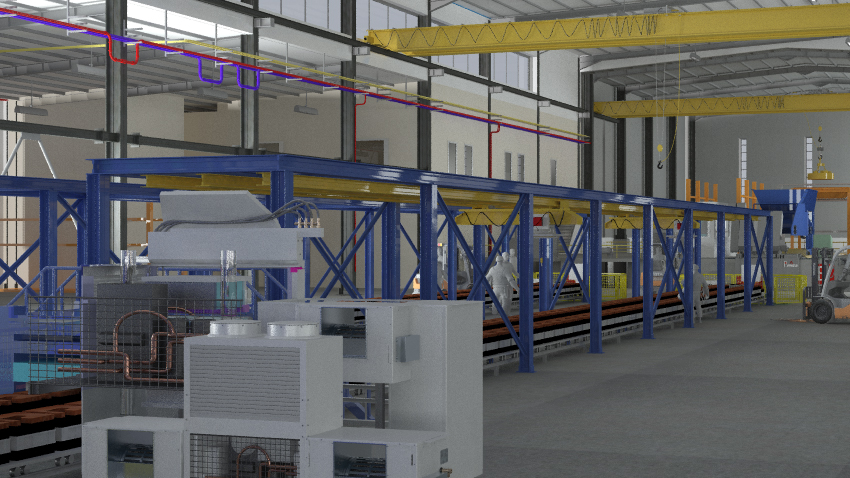

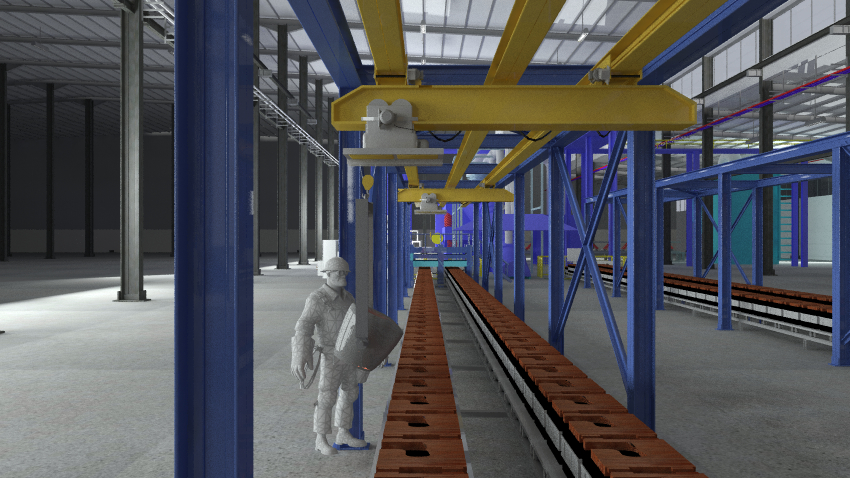

In the research, the structures that would be primarily modeled were

selected and their source information was gathered.

Location of

the factory was modeled 3D according to existing CAD Project. The usage of open

areas and passage implementation is visualized with flora (figure 5,6). All

fields and machines in the factory were modeled realistically.

Fig. 5. Gedik

Casting general model

Fig 6. Gedik

Casting outdoor model

To present animation more

realistic, kinematic characters added to scene. All levels in the production

animated separately. Modeled characters, were animated according to their task

in the factory. (Figure 5,6).

Fig. 7. Factory

interior model 1

Fig. 8. Factory

interior model 2

Conclusion

The research is important as it covers different fields of science like

archaeology, landscape planning, provincial planning, and computer-supported

animation. It is an original project thanks specifically to the utilization of

different scientific methods and the convergence of the software programs used

for different areas like remote detection, solid modeling, and animation the

research, the structures that would be primarily.

Results of this study are used for different purposes. First, the animation

of production process revealed the advantages and disadvantages of the factory

in terms of efficiency and planning.

This study will be an important guide for establishing these types of

facilities in the factory. On the other hand these high-quality images and

animations can be used in both national and international advertisement of the

factory (figure 9). Thus, the

opportunity to feel being in factory and evaluation will be provided without

visiting the factory.

Fig. 9. Process

animation

References

1. Kaplan, K., Pamir, H.,

& Parlar, T. (2009). Antik Kent ve Çevrelerinin

Görselleştirilmesi, Modellenmesi, ve Animasyonu ile Gerçek

Zamanlı Render Motorlarının Kullanımı: Antakya Kenti

Örneği. Ankara TUBITAK Proje No: 107278

2. Rohrer, M. W. (2000).

Seeing is believing: The importance of visualization in manufacturing

simulation, Proceedings of the 2000 Winter Simulation Conference, 1211-1216.

3.

Zhong, Y., Yuan, X., (2004). 3D visualization of discrete

event simulation and its applications in virtual manufacturing. International

Journal of CAD/CAM. 4 (1): pp. 19-32.