Neural Network Radial Based Function (RBF) approach in

pridicting of material removal rate and surface roughness in electrical discharge machining

Morteza Sadegh Amalnik,

Farzad Momeni,

Computer and

Automation R&D Center of ACECR-Sharif Branch,

Department of Mechanical and Industrial

Engineering, University of Qum and

Tabriz, Iran

Abstract

This paper uses Radial Based Function(RBF)

Artificial Neural Network(ANN) approach for prediction of material removal rate

and surface roughness and presents the results of the experimental

investigation. Charmilles Technology (EDM-Robofil machine) in the mechanical

engineering department is used for machining parts. The networks have four inputs of current (I),

voltage (V), Period of pulse on (Ton) and period of pulse off (Toff)

as the input processes variables. Two outputs results of material removal rate

(MRR) and surface roughness (Ra) as performance characteristics. In order to

train the network, and capabilities of the models in predicting material removal

rate and surface roughness, experimental data are employed. Then the output of

MRR and Ra obtained from RBF neural net compare with experimental

results, and amount of relative error is calculated.

Keywords:

Electro-discharge machining (EDM), Artificial Neural Networks (ANN), RBF

Introduction:

Electro-discharge machining (EDM) is

non-conventional, process, which erodes material from the work piece by a

series of discrete sparks between a work-piece and tool electrode immersed in a

liquid dielectric medium [1]. Operation and process planning, parametric

analysis, verification of the experimental results, and improving the process

performance by implementing/incorporating some of the theoretical findings [2].

A systematic study of the phenomenon of the electrical discharge in a liquid

dielectric has proven to be very difficult due to its complexity. The erosion

by an electric discharge involves phenomena such as heat conduction, melting,

evaporation, ionization, formation, and collapse of gas bubbles and energy

distribution in the discharge channel. These complicated phenomena coupled with

surface irregularities of electrodes, interactions between two successive

discharges, and the presence of debris particles make the process too abstruse,

so that complete and accurate physical modeling of the process has not been

established yet [3,4]. There are a lot of theoretical studies concerned with

microscopic metal removal arising from a single spark, the effects being

modeled from heat conduction theory [5,6,7and 8]. Recent established models for

EDM are mainly based on empirical data or basically data driven models.

Ghoreishi and Atkinson [9, 10] employed statistical modeling and process

optimization for the case of EDM drilling and milling. Wang and Tsai [11, 12]

proposed semi-empirical models of the material removal rate, surface finish and

tool wear on the work and the tool for various materials in EDM, employing

dimensional equations based on relevant process parameters for the screening

experiments and the dimensional analysis. Artificial neural networks (ANNs), as

one of the most attractive branches in artificial intelligence, has the

potentiality to handle problems such as modeling, estimating, prediction,

diagnosis, and adaptive control in complex non-linear systems [13]. The

capabilities of ANNs in capturing the mathematical mapping between input

variables and output features are of primary significance for modeling

machining processes. The use of neural networks in both EDM and wire-EDM

(WEDM) processes has also been reported. Kao and Tamg [14]. Liu and Tamg [15]

have employed feed forward neural networks with hyperbolic tangent functions

and abductive networks for the classification and on-line recognition of

pulse-types. Based on their results, discharge pulses have been identified and

then used for controlling the EDM machine. Indurkhya and Rajurkar [16]

developed a 9-9-2-size back propagation neural network for orbital EDM

modeling. Spedding and Wang [17, 18], and Tamg et al. [19] have developed BP neural

networks for modeling of WEDM. Experimental results have shown that the cutting

performance of WEDM can be greatly enhanced using the neural model. Tsai and

Wang [20] have been presented seven models for predictions of surface finish

and material removal rate of work in EDM process.

1.

Artificial neural network models of the EDM process

In the

current work, three supervised neural networks for modeling the EDM process are

compared. The first one is a Logistic Sigmoid Multi-layer Perceptron (LOGMLP);

the Second is a Hyperbolic Tangent sigmoid Multi-layer Perceptron (TANMLP) and

third is a Radial Basis Network (RBN) with Gaussian activation functions. The

LOGMLP and TANMLP are two different BP neural networks. The LOGMLP is a Back

propagation neural network with log-sigmoid transfer function in hidden layer

and output layer, but the TANMLP is a Back propagation neural network with

tangent-sigmoid transfer function in hidden layer and output layer. The BP

Neural Network is very popular, especially in the area of manufacturing

modeling, as its design and operation are relatively simple. The radial basis

network has some additional advantages such as rapid convergence and less error.

In particular, most commonly used RBNs involve fixed basis functions with

linearly appearing unknown parameters in the output layer. Radial Basis

networks may require more neuron than standard feed-forward back propagation

networks, but often they can be designed in a fraction of the time it takes to

train standard feed-forward networks. They work best when many training vectors

are available. It is commonly known that linearity in parameters in RBN allow

the use of least squares error based updating schemes that have faster

convergence than the gradient-descent methods used to update the nonlinear

parameters of multi-layer BP ANN. In practice, the number of parameters in RBN

starts becoming unmanageably large only when the number of input features increases

beyond about 10 or 20, which is not the case in our study. Hence, the use of

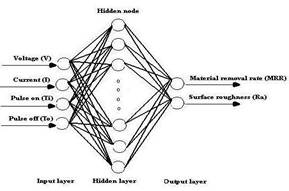

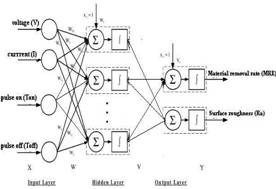

RBN was practically possible for our problem. The general input and output for

RBFNN is demonstrated in figure(1) and figure(2). MATLAB Neural Network Tool Box was used as a

platform to create the networks.

|

|

|

|

Figure1.Input

and output neural network with one

hidden layer |

Figure2.

Architecture of the RBFN. |

2.

Experimental details

In order to

obtain different machining process parameters and output features for training

and testing of neural networks, a series of experiments was performed on a

ROBOFORM 200 machine. At first, some preliminary tests were carried out to

determine the stable domain of the machine parameters and also the different

ranges of process variables. Based on preliminary tests results and working

characteristics of the EDM machine, discharge current (I), period of pulse on

(Ti), Period of pulses off (To) and source voltage (V) were chosen as

independent input parameters. During these experiments, by altering the values

of the input parameters in different levels, stable states of the machining

conditions have also been specified.

Accordingly, the experiments were

conducted with three levels of discharge current, three levels of period of

pulses on, three levels of period of pulses off and three levels of source

voltage. Table 1 shows the input process variables and their levels in the

experiments.

Throughout

the experiments, SPK steel and commercial copper was used as work-piece and

tool electrode materials. Also, the dielectric fluid used was elf oil.

Particular attention was paid to ensuring that operating conditions permitted.

Effective flushing of machining debris

from the working region. Thus, the experiments were done in the planning

process mode in which the bottom surface of the electrode is flat and parallel

to the work-piece surface. Also, the diameter of cylindrical electrode was

equal to the diameter of the round bar work-piece and was chosen to be 12 mm.

The total data obtained from machining experiments (3*3*3*3) is 81 and these

forms the neural networks' training and testing sets. To achieve validity and

accuracy, each test was repeated three times. Material removal rate (MRR) and

surface roughness (Ra) were assigned as performance characteristics or process

outputs, since the performance of any machining process is evaluated in terms

of these two measures. Then, the mean values of the three response measurements

(MRR and Ra) were used as output at each set of parameters. The machining time

considered for each test was dependent on the discharge current and much time

was allocated to the tests with lower current. The material removal rate (MRR)

was estimated by weighing the work-piece on a digital single pan balance before

and after the experiments and was reported in gr/hr unit. The surface roughness

(Ra) was measured by means of a Mahr with Ra value in microns at a cut-off

length of 0.8 mm.

Table 1.

Pertinent process parameters and their levels for machining experiments.

|

Process

parameters |

Operating conditions |

|

Source

voltage V (v) |

80,160,200 |

|

Discharge

current I (A) |

6,16,48 |

|

Period of pulses on

Ti ( |

6.4,100,800 |

|

Period of

pulses off To ( |

12.8,50,400 |

For

normalization of input and output variable, the following linear mapping

formula is used:

![]()

Modeling of

EDM process with RBF network are composed of two stages: training and testing

of the networks with experimental machining data. The training data consisted

of values for current (I), period of pulses on (Ti), period of pulses off (To),

and source voltage (V), and the corresponding material removal rate (MRR) and

surface roughness (Ra). In all, 81 such data sets were used, of which 66 data

sets were selected at random and used for training purposes while the remaining

15 data sets were presented to the trained networks as new application data for

verification (testing) purposes. Thus, the networks were evaluated using data

that had not been used for training.

In RBF

neural network, two parameters need to be defined. Spread factor and goal factor.

The spread factor S, has to be

specified depending on the particular case in hand. It has to be smaller than

the highest limit of the input data and larger than the lowest limit [20].

Based on this, and assuming that all the training data is mapped between -1 and

1. The goal factor value is set to zero, since error is a decisive factor in

this study. Table 2 shows the 15 experimental data sets, which are used for

verifying or testing network capabilities in modeling the process. Therefore,

the general network structure is supposed to be 4-n-2, which implies 4 neurons

in the input layer, n neurons in the hidden layer, and 2 neurons in the output

layer. Then, by varying the number of hidden neurons and spread factor,

different network configurations are

trained, and their performances are checked. The results are shown in table

3.1, 3.2 and 3.3.

3.

Results

3.1.

Training results

Each

experimental set (except the validation set) is used to train each network.

This training is repeated for each topology. The performance is measured by the

linear regression (R) of each

output. With this analysis it is possible to determine the response of the

network with respect to the targets. A value of 1 indicates that the network is

perfectly simulating the training set while 0 means the opposite. For all the

cases in this study, the value of R (for

all output sets) is shown in Table 5. The case of RBN showed a good fitting

pattern for all the cases) as expected since the goal error factor is set to

zero.

3.2.

Validation results of the LOGMLP, TANMLP and RBF model

As a

result, from table 3.1, the best network structure of BP model is picked to

have 10 neurons in the hidden layer with the average verification errors of

20.31% and 5.13% in predicting MRR and Ra, respectively, for TANMLP. Thus, it

has a total average error of 12.72% over the 15 experimental verification data

sets. And from table 3.2, the best network structure of BP model is picked to

have 11 neurons in the hidden layer with the average verification errors of

32.02% and 12.91% in predicting MRR and Ra, respectively, for LOGMLP. Thus, it

has a total average error of 22.47% over the 15 experimental verification data

sets. As a result, from table 3.3, the best network of RBF model is picked to

have 66 neurons in hidden layer, while spread factor is 0.07.The average

verification errors of 17.54% and 7.84% in predicting MRR and Ra, respectively.

Thus it has a total error of 12.69% over the 15 experimental verification data

test. Table 4.1,4.2 and 4.3 shows the comparison of experimental and predicted

values for MRR and Ra in verification cases by three neural network models.

Table

2. Machining conditions for verification experiments

|

V (v) |

I (A) |

Ti ( |

To( |

MRR

(gr/hr) |

Ra( |

|

80 |

6 |

6.4 |

400 |

0.2 |

2.62 |

|

80 |

6 |

800 |

12.8 |

0.3 |

2.87 |

|

80 |

16 |

6.4 |

400 |

0.3 |

3.05 |

|

80 |

16 |

800 |

12.8 |

10.0 |

7.63 |

|

80 |

48 |

100 |

12.8 |

63.0 |

9.75 |

|

160 |

6 |

800 |

12.8 |

0.2 |

2.68 |

|

160 |

16 |

100 |

12.8 |

20.4 |

8.32 |

|

160 |

16 |

800 |

50 |

12.8 |

7.85 |

|

160 |

48 |

100 |

12.8 |

55.1 |

9.31 |

|

160 |

48 |

800 |

400 |

44.0 |

10.61 |

|

200 |

6 |

6.4 |

400 |

0.3 |

2.05 |

|

200 |

6 |

800 |

50 |

0.3 |

2.69 |

|

200 |

16 |

100 |

12.8 |

21.6 |

8.32 |

|

200 |

48 |

6.4 |

12.8 |

7.6 |

4.27 |

|

200 |

48 |

800 |

50 |

54 |

10.43 |

|

Test No. |

V (v) |

I (A) |

Ti ( |

To( |

MRR

(gr/hr) |

Ra( |

|

1 |

80 |

6 |

6.4 |

400 |

0.2 |

2.62 |

|

2 |

80 |

6 |

800 |

12.8 |

0.3 |

2.87 |

|

3 |

80 |

16 |

6.4 |

400 |

0.3 |

3.05 |

|

4 |

80 |

16 |

800 |

12.8 |

10.0 |

7.63 |

|

5 |

80 |

48 |

100 |

12.8 |

63.0 |

9.75 |

|

6 |

160 |

6 |

800 |

12.8 |

0.2 |

2.68 |

|

7 |

160 |

16 |

100 |

12.8 |

20.4 |

8.32 |

|

8 |

160 |

16 |

800 |

50 |

12.8 |

7.85 |

|

9 |

160 |

48 |

100 |

12.8 |

55.1 |

9.31 |

|

10 |

160 |

48 |

800 |

400 |

44.0 |

10.61 |

|

11 |

200 |

6 |

6.4 |

400 |

0.3 |

2.05 |

|

12 |

200 |

6 |

800 |

50 |

0.3 |

2.69 |

|

13 |

200 |

16 |

100 |

12.8 |

21.6 |

8.32 |

|

14 |

200 |

48 |

6.4 |

12.8 |

7.6 |

4.27 |

|

15 |

200 |

48 |

800 |

50 |

54 |

10.43 |

Table3.1.The

effects of different number of hidden neurons on the TANMLP

|

(No.

Of hidden neuron |

Epoch |

Average

error in MRR (%) |

Average

error in Ra (%) |

Total

average error (%) |

|

8 |

1529 |

43.59 |

6.47 |

25.03 |

|

9 |

1042 |

28.44 |

7.22 |

17.83 |

|

10 |

1137 |

20.31 |

5.13 |

12.72 |

|

11 |

2076 |

35.47 |

8.44 |

21.96 |

Table3.2.The

effects of different number of hidden neurons on the LOGMLP

|

No. Of

hidden neuron |

Epoch |

Average

Error in MRR (%) |

Average Error in

Ra (%) |

Total

Average Error (%) |

|

6 |

7437 |

36.42 |

10.45 |

23.44 |

|

7 |

1244 |

42.28 |

9.23 |

25.76 |

|

8 |

334 |

48.72 |

10.60 |

29.66 |

|

9 |

572 |

37.61 |

14.48 |

26.05 |

|

10 |

311 |

75.14 |

12.18 |

43.66 |

|

11 |

848 |

32.83 |

12.91 |

22.87 |

|

15 |

542 |

67.54 |

9.31 |

38.43 |

Table 3.3.

The effects of different spread factor on the RBF model (Radial Basis Network)

|

Spread

factor |

Average Error in MRR (%) |

Average Error in

Ra (%) |

Total Average Error (%) |

|

0.01 |

21.00 |

7.41 |

14.21 |

|

0.03 |

20.81 |

7.17 |

13.99 |

|

0.05 |

20.54 |

7.23 |

13.89 |

|

0.06 |

19.48 |

7.41 |

13.45 |

|

0.07 |

17.54 |

7.84 |

12.69 |

|

0.08 |

20.87 |

9.02 |

14.95 |

|

0.09 |

24.98 |

10.28 |

17.63 |

|

0.1 |

28.17 |

11.51 |

19.84 |

|

0.12 |

35.85 |

13.66 |

24.76 |

|

0.15 |

46.04 |

16.01 |

31.03 |

Table4.1.

Comparison of MRR and Ra measured and predicted by the TANMLP neural network

|

Test No. |

MRR

(gr/hr) |

Ra ( |

Error (%) |

|||

|

Experimental |

TANMLP

model |

Experimental |

TANMLP

model |

Error in MRR

|

Error in

Ra |

|

|

1 |

0.2 |

0.15 |

2.62 |

2.38 |

25.00 |

9.16 |

|

2 |

0.3 |

0.31 |

2.87 |

2.85 |

3.33 |

0.7 |

|

3 |

0.3 |

0.19 |

3.05 |

2.88 |

36.67 |

5.57 |

|

4 |

10.0 |

8.96 |

7.63 |

7.79 |

10.4 |

2.1 |

|

5 |

63.0 |

63.69 |

9.75 |

9.24 |

1.11 |

5.23 |

|

6 |

0.2 |

0.4 |

2.68 |

2.80 |

100.00 |

4.48 |

|

7 |

20.4 |

20.79 |

8.32 |

8.12 |

1.91 |

2.40 |

|

8 |

12.8 |

12.45 |

7.85 |

7.72 |

2.73 |

1.66 |

|

9 |

55.1 |

62.61 |

9.31 |

8.85 |

13.63 |

4.94 |

|

10 |

44.0 |

43.00 |

10.61 |

10.54 |

2.27 |

0.66 |

|

11 |

0.3 |

0.18 |

2.05 |

2.38 |

40.00 |

16.10 |

|

12 |

0.3 |

0.41 |

2.69 |

2.80 |

36.67 |

4.09 |

|

13 |

21.6 |

16.40 |

8.32 |

8.37 |

20.07 |

0.60 |

|

14 |

7.6 |

7.85 |

4.27 |

3.45 |

3.29 |

19.20 |

|

15 |

54 |

55.90 |

10.43 |

10.44 |

3.52 |

0.10 |

Table4.2.

Comparison of MRR and Ra measured and predicted by the LOGMLP neural network

|

No. of

Experiments |

MRR

(gr/hr) |

Ra ( |

Error (%) |

|||||||

|

Experimental |

LOGMLP

model |

Experimental |

LOGMLP

model |

Error in MRR

|

Error in

Ra |

|||||

|

1 |

0.2 |

0.14 |

2.62 |

2.41 |

30.00 |

8.02 |

||||

|

2 |

0.3 |

0.20 |

2.87 |

2.89 |

33.33 |

0.70 |

||||

|

3 |

0.3 |

0.17 |

3.05 |

3.05 |

43.33 |

0.00 |

||||

|

4 |

10.0 |

11.98 |

7.63 |

7.62 |

19.80 |

0.13 |

||||

|

5 |

63.0 |

54.27 |

9.75 |

9.36 |

13.86 |

0.40 |

||||

|

6 |

0.2 |

0.18 |

2.68 |

3.48 |

10.00 |

29.85 |

||||

|

7 |

20.4 |

0.12 |

8.32 |

8.13 |

99.41 |

2.28 |

||||

|

8 |

12.8 |

12.86 |

7.85 |

7.70 |

0.47 |

1.91 |

||||

|

9 |

55.1 |

55.70 |

9.31 |

8.23 |

1.09 |

11.60 |

||||

|

10 |

44.0 |

45.86 |

10.61 |

10.96 |

4.23 |

3.30 |

||||

|

11 |

0.3 |

0.21 |

2.05 |

2.10 |

36.67 |

2.44 |

||||

|

12 |

0.3 |

0.17 |

2.69 |

2.76 |

43.33 |

7.00 |

||||

|

13 |

21.6 |

0.12 |

8.32 |

6.98 |

99.44 |

16.11 |

||||

|

14 |

7.6 |

11.56 |

4.27 |

4.01 |

52.11 |

6.09 |

||||

|

15 |

54 |

56.89 |

10.43 |

10.80 |

5.35 |

3.55 |

||||

Table4.3.

Comparison of MRR and Ra measured and predicted by the RBF neural network model

|

No. of

Experiments |

MRR

(gr/hr) |

Ra ( |

Error (%) |

|||

|

Experimental |

LOGMLP model |

Experimental |

LOGMLP

model |

Error in MRR |

Error in Ra |

|

|

1 |

0.2 |

0.3 |

2.62 |

2.74 |

50.00 |

4.58 |

|

2 |

0.3 |

0.1 |

2.87 |

2.59 |

66.67 |

9.76 |

|

3 |

0.3 |

0.3 |

3.05 |

2.74 |

0.00 |

10.16 |

|

4 |

10.0 |

9.3 |

7.63 |

7.56 |

7.00 |

0.92 |

|

5 |

63.0 |

54.41 |

9.75 |

9.14 |

13.63 |

6.26 |

|

6 |

0.2 |

0.2 |

2.68 |

2.99 |

0.00 |

11.57 |

|

7 |

20.4 |

14.58 |

8.32 |

7.90 |

28.53 |

5.05 |

|

8 |

12.8 |

13.2 |

7.85 |

7.18 |

3.13 |

8.54 |

|

9 |

55.1 |

54.71 |

9.31 |

8.63 |

0.71 |

7.30 |

|

10 |

44.0 |

52.0 |

10.61 |

10.21 |

18.18 |

3.77 |

|

11 |

0.3 |

0.3 |

2.05 |

2.86 |

0.00 |

39.51 |

|

12 |

0.3 |

0.4 |

2.69 |

2.66 |

33.33 |

1.12 |

|

13 |

21.6 |

14.21 |

8.32 |

7.65 |

34.26 |

8.05 |

|

14 |

7.6 |

7.3 |

4.27 |

4.29 |

3.95 |

0.47 |

|

15 |

54.0 |

56.0 |

10.43 |

10.37 |

3.70 |

0.58 |

Table

5. Different value of Correlation Coefficient (R)

|

(R)

Coefficient |

RBF model |

TANMLP

model |

LOGMLP

model |

|

R

coefficient for MRR |

0.996 |

0.993 |

0.963 |

|

R

coefficient for Ra |

0.993 |

0.996 |

0.988 |

Conclusions

and summary

In this paper,

three types of supervised neural networks LOGMLP, TANMLP and RBF have been used

to successfully model EDM process. An effort was made to include as many

different machining conditions as possible that influence the process. Based on

the results of testing each network with some data set which was different from

those used in the training phase, it was shown that RBF neural model has

superior performance than TANMLP and LOGMLP network model. In summary, the

following items can also be mentioned as the general findings of the present

research:

1. The

TANMLP, LOGMLP and RBF neural networks are capable of constructing models using

only experimental data describing proper machining behavior. This is the main

attraction of neural networks, which make them suitable for the problem at

hand.

2. Modeling

accuracy with RBF neural networks is better than TANMLP and LOGMLP. As a

result, from table 5, the difference between correlation coefficients (R) for

TANMLP and RBF is negligible, because of small difference between their average

errors.

3.

Discharge current is the dominant factor among the other input parameters, so

that, increasing current in a constant level of pulse period and gap voltage,

increases MRR and Ra steadily. A high discharge energy associated with high

current is capable of removing a chunk of material leading to the formation of

a deep and wide crater, and hence, worsening the machined surface quality.

4. For the

effect of pulse period, initially, it is observed that for all values of gap

voltage and a constant current, material removal rate and surface roughness

increase with increasing pulse period, but these trends continue until about

400 ![]() sec of pulse period in which MRR gains its maximum value.

Although, it is generally understood that increasing pulse period, and hence,

pulse-on time, results in greater discharge energy, but with too long pulse

durations, the results become reverse.

This is mainly because of undesirable heat dissipation phenomena of the thermal

energy liberated during discharge, which in turn lessens the erosive effects of

sparks.

sec of pulse period in which MRR gains its maximum value.

Although, it is generally understood that increasing pulse period, and hence,

pulse-on time, results in greater discharge energy, but with too long pulse

durations, the results become reverse.

This is mainly because of undesirable heat dissipation phenomena of the thermal

energy liberated during discharge, which in turn lessens the erosive effects of

sparks.

5. In

normal EDM, the discharge voltage (V), influenced primarily by the electrode

and work piece materials, is somehow constant so that an increase in source

voltage will have little effect on the discharge energy for a given pair of

electrode-work piece. Hence, increasing source voltage alone, does not

necessarily confirms the availability of high discharge voltage, which directly

affects MRR and Ra.

References

1.

R.E. Williams and K.P. Rajurkar, Study of

wire electrical discharge machined surface characteristics,

J.Mater.Pro.Tech, 28, 1991

2.

N.K. Jain and V.K. Jain, Modeling of material removal in mechanical

type advanced machining processes: a state-of-art review, IntJ.Mach.Tools

Manuf. , 41(2001), PP. 1573-1635.

3.

S.M. Pandit and K.P. Rajurkar, A stochastic approach to thermal modeling

applied to electro-discharge machining, Trans.ASME J. Heat Transfer,

105(1983), PP.555-562.

4.

J.A. McGeough, Advanced Methods of Machining, Chapman and Hall, London and New York, 1988.

5.

F. Van Djick, Physico-mathematical analysis of the electro-discharge machining ,

Ph.D.Thesis, Catholic Un., of Leuven, Belgium, 1973.

6.

A. Erden and B. kaftanoglu. Heat transfer modeling of electric discharge

machining, 21" MTDR

Conference, Swansea, UK, Macmillan Press Ltd., 1980, PP.351-358.

7.

S.T. Jilani and P.C. Pandey, Analysis and modeling of EDM parameters.

Precision Eng., 4(4) (1982), PP.215-221.

8.

A. Singh and A. Ghosh, A thermoelectric model of material removal

during electric discharge machining, IntJ.Mach.Tools Manufact,

39(1999), PP.669-682.

9.

M. Ghoreishi and J. Atkinson, Vibro-rotary electrode: a new technique in

EDM drilling, performance

evaluation by statistical

modeling and optimization, ISEM XIII, Spain, 2001

10.

M. Ghoreishi and J. Atkinson, A comparative

experimental study of machining

characteristics in vibratory, rotary and vibro-rotary electro-discharge

machining, J.Mat.Proc.Tech.,120(2002),PP.374-384.

11.

P.J. Wang and K.M. Tsai, Semi-empirical model on •work removal and

tool •wear in electrical discharge machining, J.Mater.Proc.Tech.,

114(2001), PP.1-17.

12.

K.M. Tsai and P.J. Wang, Semi-empirical model of surface finish on

electrical discharge machining, IntJ.Mach.Tools Manufact.,

41(2001), PP. 1455-1477.

13.

J.A. Freeman and D.M. Skapura, Neural Networks: algorithms, applications,

and programming tech., Addision-Wesley, Reading.MA, 1992

14.

J.Y. Kao and Y.S. Tamg, A neural-network approach for the on-line monitoring

of the electrical discharge machining process, J.Mater.Proc.Tech, 69(1997), PP.112-119.

15.

H.S. Liu and Y.S. Tamg, Monitoring of the electrical discharge

machining process by abductive

networks, Int.J.Adv.ManufactTech., 13(1997), PP.264-270.

16.

G. Indurkhya and K.P. Rajurkar, Artificial neural network approach in

modeling of EDM

process, in: Proc.ArtifIcial

neural networks in engineering (ANNIE92) conf., St. Louis,

Missouri, USA, 15-18 November 1992, PP.845-850.

17.

T.A. Spedding and Z.Q. Wang, Study on modeling of wire EDM process, J.Mater.Proc.Tech.,

69(1997), PP. 18-28.

18.

T.A. Spedding and Z.Q. Wang, Parametric

optimization and surface characterization of wire electrical

discharge machining process. Precision Engineering, 20(1997), PP.5-15.

19.

Y.S. Tamg, S.C. Ma and L.K. Chung,

Determination of optimal cutting parameters in wire electrical discharge

machining, Int J. Mach. Tools

Manufact,35(1995), PP.1693-1701.

20.

K.M.Tsai,P.J.Wang,Prediction on surface

finish in electrical discharge machining based upon neural net, IntJ.Mach.Tools

Manuf, 41,2001